Difference between revisions of "ESC1"

Rlorentzen (talk | contribs) |

|||

| Line 1: | Line 1: | ||

| − | [[File:ESC-1.jpg|thumb|alt=ESC-1.|ESC-1]] | + | [[File:ESC-1.jpg|thumb|alt=ESC-1.|500px|ESC-1]] |

'''Exigo System Controller''' | '''Exigo System Controller''' | ||

| Line 14: | Line 14: | ||

| − | The Exigo System Controller is designed for use in marine/offshore and onshore environments. The construction is | + | The Exigo System Controller is designed for use in marine/offshore and onshore environments. The construction is extremely robust and can handle mobile environments as well as stationary, temperature controlled rooms. The system controller is based on IP technology, giving it extreme flexibility, superb audio quality and huge integration possibilities. |

| − | extremely robust and can handle mobile environments as well as stationary, temperature controlled rooms. The system | ||

| − | controller is based on IP technology, giving it extreme flexibility, superb audio quality and huge integration possibilities. | ||

| − | The system controller handles routing and prioritization of up to 32 simultaneous audio channels in the system. The audio | + | The system controller handles routing and prioritization of up to 32 simultaneous audio channels in the system. The audio can be distributed from up to 150 audio inputs to up to 250 zones. |

| − | can be distributed from up to 150 audio inputs to up to 250 zones. | ||

| − | The system controller features a display where status and faults can be viewed. This display also allows configuration of | + | The system controller features a display where status and faults can be viewed. This display also allows configuration of simple parameters. The system controller monitors and receives status information from every component in the system. Faults are time stamped, and presented in chronological order on the display. Buttons allow an operator to acknowledge and reset faults. The network connection to every component in the system is monitored, so a defect switch or broken cable will be detected just as reliably and fast as any other fault in the system. |

| − | simple parameters. The system controller monitors and receives status information from every component in the system. | ||

| − | Faults are time stamped, and presented in chronological order on the display. Buttons allow an operator to acknowledge | ||

| − | and reset faults. The network connection to every component in the system is monitored, so a defect switch or broken | ||

| − | cable will be detected just as reliably and fast as any other fault in the system. | ||

| − | The system controller also acts as the system’s alarm generator and audio message storage. The embedded alarm | + | The system controller also acts as the system’s alarm generator and audio message storage. The embedded alarm generator features a set of the most common alarm tones, but can also be programmed to support custom alarm tones |

| − | generator features a set of the most common alarm tones, but can also be programmed to support custom alarm tones | ||

and patterns. Stored voice and audio messages is easily uploaded to the system controller as standard .wav files. | and patterns. Stored voice and audio messages is easily uploaded to the system controller as standard .wav files. | ||

| − | The system controller’s control inputs/outputs and audio inputs can be used locally by the system controller (e.g. for PTT | + | The system controller’s control inputs/outputs and audio inputs can be used locally by the system controller (e.g. for PTT and audio from a handheld microphone) or can be controlled by the system (e.g. audio input for background music). |

| − | and audio from a handheld microphone) or can be controlled by the system (e.g. audio input for background music) | ||

| − | |||

| − | |||

| − | |||

| − | |||

| + | For increased functionality, one optional function board can be inserted in the system controller. This will allow the controller to connect to 6 analog intercom stations or 12 analog telephones. The function board can also be used to supply the system controller with 12 additional analog audio inputs/outputs. | ||

== Additional documentation == | == Additional documentation == | ||

For more documentation, please visit the Zenitel web page: https://www.zenitel.com/product/esc-1 | For more documentation, please visit the Zenitel web page: https://www.zenitel.com/product/esc-1 | ||

| + | |||

| + | == Installation == | ||

| + | === Overview - Front === | ||

| + | [[File:ESC1 Overview Front.PNG|left|ESC1]] | ||

| + | <br style="clear:both;" /> | ||

| + | {| border="1" | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 1 || align="left" | Mounting Flange || align="left"| The mounting flanges are used to mount the unit in 19” equipment racks | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 2 || align="left" | Ventilation Inlets || align="left"| The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 3 || align="left" | Headphone Jack || align="left"| Headphones can be connected for listening to the different audio streams in the system | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 4 || align="left" | Status Indicators || align="left"| The status indicators are used to display the status of important parameters such as power supplies and faults | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 5 || align="left" | LCD Display || align="left"| The LCD screen displays status and a graphical user interface | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 6 || align="left" | Control Knob || align="left"| The control knob is used to select and execute menu items in the user interface. The knob can be rotated and pressed. | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 7 || align="left" | Front Cover || align="left"| The front cover can be opened in order to gain access to the primary system controller board and the optional function board slot | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 8 || align="left" | Cover Screws || align="left"| The two cover screws secure the front cover in place. To open the front cover, these two screws must be loosened and pulled out 1.5 – 2 cm. The screws can then be used as handles to pull out the front cover | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 9 || align="left" | Integrated Handle || align="left"| These integrated handles make it easy to maneuver the unit, without adding to the installation depth | ||

| + | |- | ||

| + | |} | ||

| + | <br> | ||

| + | ----------- | ||

| + | |||

| + | === Overview - Back === | ||

| + | [[File:ESC1 Overview Back.PNG|left|ESC1]] | ||

| + | <br style="clear:both;" /> | ||

| + | {| border="1" | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 1 || align="left" | Ethernet Ports || align="left"| Redundant Ethernet connections for audio and control data | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 2 || align="left" | Serial Ports || align="left"| RS-232 for console and RS-232/422/485 for integration with other equipment | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 3 || align="left" | Control Inputs || align="left"| Six configurable control inputs that can be optionally monitored. Each input is activated by closing the loop between the two terminals | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 4 || align="left" | Fault Relay Output || align="left"| A switching relay (NO, NC & COM) is used to indicate faults in the system | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 5 || align="left" | Control Outputs || align="left"| Six configurable control outputs. Each is made of a switching relay (NO, NC and COM) in parallel with a 24VDC signal. The 24VDC part of the control output can source max 200mA and has overcurrent protection. | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 6 || align="left" | Audio Input || align="left"| Microphone and line-in audio inputs for microphones or external audio sources | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 7 || align="left" | Audio Output || align="left"| One configurable audio output which can be used for analog integration | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 8 || align="left" | Optional Audio I/O || align="left"| Audio inputs/outputs available in the system if the optional AGA board is inserted in the ESC1 | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 9 || align="left" | Ground Connection || align="left"| Ground connection for grounding of the unit. This is connected in parallel with the ground connection in the AC power inlet | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 10 || align="left" | DC Power Inlet || align="left"| DC power inlet for 24 to 48 VDC | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 11 || align="left" | AC Power Switch || align="left"| Power switch for AC power. This switch will not turn off the system controller if DC backup is connected | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 12 || align="left" | AC Power Inlet || align="left"| AC power inlet for 110 to 230 VAC. The power inlet has a V-Lock mechanism for a secure connection | ||

| + | |- | ||

| + | |} | ||

| + | <br> | ||

| + | ----------- | ||

| + | |||

| + | === Overview - Internal === | ||

| + | [[File:ESC1 Overview Internal.PNG|left|ESC1]] | ||

| + | <br style="clear:both;" /> | ||

| + | {| border="1" | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 1 || align="left" | Feature board slot || align="left"| Slot for an optional feature board like the AGA board for 12 additional audio inputs/outputs | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 2 || align="left" | PSC slot || align="left"| Slot for the primary system controller board | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 3 || align="left" | PSC Hotswap || align="left"| | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 4 || align="left" | PSC Eth0 || align="left"| | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 5 || align="left" | Status indicators || align="left"| Local status indicators for the primary system controller board | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 6 || align="left" | Hotswap || align="left"| | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 7 || align="left" | Primary System Controller || align="left"| Primary System Controller board for the ESC1 | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 8 || align="left" | SIM card || align="left"| SIM card containing the ESC1’s MAC address and basic settings | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 9 || align="left" | SSC Serial Connector || align="left"| | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 10 || align="left" | Battery || align="left"| Battery for the time clock | ||

| + | |- | ||

| + | |} | ||

| + | <br> | ||

| + | ----------- | ||

| + | |||

| + | === Placement === | ||

| + | The ESC1 can be l ocated anywhere in the equipment rack. It is however advisable to install it at eye-level as this will make it easier to operate the user interface on the display. | ||

| + | |||

| + | === Mounting === | ||

| + | The ESC1’s mechanical construction is rigid enough to be mounted using only the four holes in the mounting flange to secure it to the rack. It is however considered good practice to mount support rails if the system is installed in a moving environment. | ||

| + | |||

| + | === Power Supply === | ||

| + | The ESC1 shall be connected to the equipment rack’s primary and secondary (emergency) source of power. | ||

| + | |||

| + | The requirements for the power rails are listed in Table 3. The cables used for power shall be dimensioned accordingly to the voltage and current consumption of the ESC1. | ||

| + | |||

| + | [[File:Note.PNG]] | ||

| + | ''Only one power source may be connected if the power source itself is redundant'' | ||

| + | ''(e.g. UPS) or if the class/installation permits a single source of power.'' | ||

| + | |||

| + | [[File:Observe.PNG]] | ||

| + | ''Both power inputs are equipped with a lock, preventing the plug from falling out.'' | ||

| + | ''Make sure that the plug is properly inserted, and that the lock is engaged.'' | ||

| + | |||

| + | === Grounding === | ||

| + | It is always good practice to ground the cabinet of equipment installed in racks. This ensures safety and good EMC. If the unit is powered entirely through the DC power inlet, the ground connection is the only way to connect the ESC1 to ground. The grounding connection of the ESC1 should be connected to the equipment rack’s ground strip using a ground wire of at least 0.75 mm² (AWG 19). | ||

| + | |||

| + | === Installing Primary System Controller Board === | ||

| + | The primary system controller (PSC) or AMC-IP board must be inserted into the system controller. Before inserting the PSC board into the system controller, the SIM card containing the MAC address and basic settings must be inserted into the board. The SIM card shall be mounted in the socket located in the lower corner of the board (See Figure 10) by sliding the metal retention clip back and flipping the lid open (the lid itself comprises the socket). The SIM card itself shall then be inserted into the socket before closing it and the retention clip fastened. | ||

| + | |||

| + | To install the PSC board, the front cover must be opened by unscrewing the two front cover retention screws. Open the front cover by pulling it out (using the two loosened screws as handles) and flipping it down. The PSC board shall be inserted in the lowest position. | ||

| + | |||

| + | [[File:Warning.PNG]] '''''Disconnect all power from the ESC1 before installing or removing the PSC board''''' | ||

| + | <br> | ||

| + | [[File:Observe.PNG]] ''Configuration data for all units in the system is stored in nonvolatile memory on the PSC board'' | ||

| + | |||

| + | === Ethernet Connections === | ||

| + | The ESC1 shall be connected to the network using one or two Ethernet cables, depending on the system interconnection scheme. | ||

| + | |||

| + | === Serial Port Connections to PSC === | ||

| + | The ESC1 is equipped with two serial ports on the PSC board, which can be used for external equipment integration. Serial port 0 offers RS232 only and is most commonly used for console access. Serial port 1 can be configured as either RS232 or RS422. The baud rate for both ports is configurable through software. | ||

| + | |||

| + | [[File:ESC1 SerialPorts.PNG|left|ESC1]] | ||

| + | <br style="clear:both;" /> | ||

| + | {| border="1" | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 1 || align="left" | Pin 1 - Not used || || align="center" style="background:#ffcb00;" width="50pt"| 9 || align="left" | Pin 1 - RS422 Tx+ | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 2 || align="left" | Pin 2 - Not used || || align="center" style="background:#ffcb00;" width="50pt"| 10 || align="left" | Pin 2 - RS422 Tx- | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 3 || align="left" | Pin 3 - RS232 Tx || || align="center" style="background:#ffcb00;" width="50pt"| 11 || align="left" | Pin 3 - RS232 Tx | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 4 || align="left" | Pin 4 - GND || || align="center" style="background:#ffcb00;" width="50pt"| 12 || align="left" | Pin 4 - GND | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 5 || align="left" | Pin 5 - GND || || align="center" style="background:#ffcb00;" width="50pt"| 13 || align="left" | Pin 5 - GND | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 6 || align="left" | Pin 6 - RS232 Rx || || align="center" style="background:#ffcb00;" width="50pt"| 14 || align="left" | Pin 6 - RS232 Rx | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 7 || align="left" | Pin 7 - Not used || || align="center" style="background:#ffcb00;" width="50pt"| 15 || align="left" | Pin 7 - RS232 Rx+ | ||

| + | |- | ||

| + | | align="center" style="background:#ffcb00;" width="50pt"| 8 || align="left" | Pin 8 - Not used || || align="center" style="background:#ffcb00;" width="50pt"| 16 || align="left" | Pin 8 - RS232 Rx- | ||

| + | |- | ||

| + | |} | ||

| + | <br> | ||

| + | ----------- | ||

[[Category:Hardware]] | [[Category:Hardware]] | ||

Revision as of 21:07, 2 June 2016

Exigo System Controller

- Control and routing of audio channels

- 115 - 230 VAC primary power and 24 - 48 VDC secondary power

- Redundant Ethernet connections

- Digital audio processing

- Receives, handles and stores fault messages from the system

- Interface to PABX and iPBX

- Interface to telecom management, safety, automation and security systems

- Voice message storage

- Programmable alarm generator

- Tick tone generator

The Exigo System Controller is designed for use in marine/offshore and onshore environments. The construction is extremely robust and can handle mobile environments as well as stationary, temperature controlled rooms. The system controller is based on IP technology, giving it extreme flexibility, superb audio quality and huge integration possibilities.

The system controller handles routing and prioritization of up to 32 simultaneous audio channels in the system. The audio can be distributed from up to 150 audio inputs to up to 250 zones.

The system controller features a display where status and faults can be viewed. This display also allows configuration of simple parameters. The system controller monitors and receives status information from every component in the system. Faults are time stamped, and presented in chronological order on the display. Buttons allow an operator to acknowledge and reset faults. The network connection to every component in the system is monitored, so a defect switch or broken cable will be detected just as reliably and fast as any other fault in the system.

The system controller also acts as the system’s alarm generator and audio message storage. The embedded alarm generator features a set of the most common alarm tones, but can also be programmed to support custom alarm tones and patterns. Stored voice and audio messages is easily uploaded to the system controller as standard .wav files.

The system controller’s control inputs/outputs and audio inputs can be used locally by the system controller (e.g. for PTT and audio from a handheld microphone) or can be controlled by the system (e.g. audio input for background music).

For increased functionality, one optional function board can be inserted in the system controller. This will allow the controller to connect to 6 analog intercom stations or 12 analog telephones. The function board can also be used to supply the system controller with 12 additional analog audio inputs/outputs.

Contents

Additional documentation

For more documentation, please visit the Zenitel web page: https://www.zenitel.com/product/esc-1

Installation

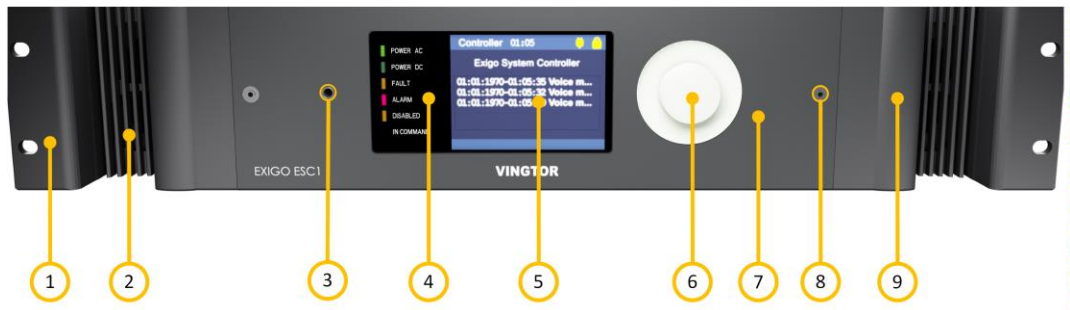

Overview - Front

| 1 | Mounting Flange | The mounting flanges are used to mount the unit in 19” equipment racks |

| 2 | Ventilation Inlets | The ventilation inlets should be kept free of obstacles and dust. Fans control the airflow based on internal temperature |

| 3 | Headphone Jack | Headphones can be connected for listening to the different audio streams in the system |

| 4 | Status Indicators | The status indicators are used to display the status of important parameters such as power supplies and faults |

| 5 | LCD Display | The LCD screen displays status and a graphical user interface |

| 6 | Control Knob | The control knob is used to select and execute menu items in the user interface. The knob can be rotated and pressed. |

| 7 | Front Cover | The front cover can be opened in order to gain access to the primary system controller board and the optional function board slot |

| 8 | Cover Screws | The two cover screws secure the front cover in place. To open the front cover, these two screws must be loosened and pulled out 1.5 – 2 cm. The screws can then be used as handles to pull out the front cover |

| 9 | Integrated Handle | These integrated handles make it easy to maneuver the unit, without adding to the installation depth |

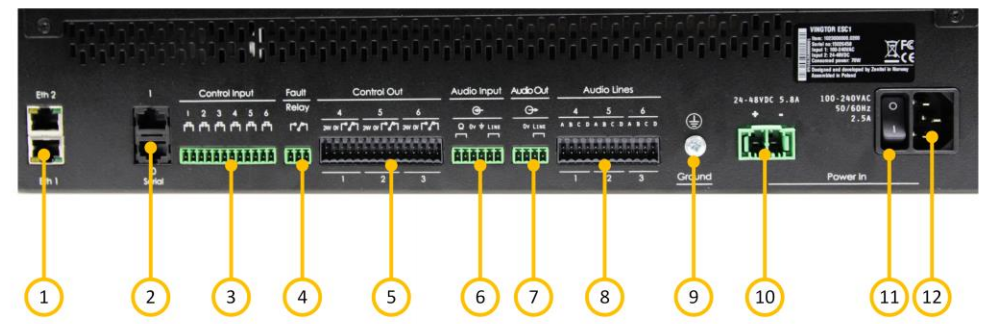

Overview - Back

| 1 | Ethernet Ports | Redundant Ethernet connections for audio and control data |

| 2 | Serial Ports | RS-232 for console and RS-232/422/485 for integration with other equipment |

| 3 | Control Inputs | Six configurable control inputs that can be optionally monitored. Each input is activated by closing the loop between the two terminals |

| 4 | Fault Relay Output | A switching relay (NO, NC & COM) is used to indicate faults in the system |

| 5 | Control Outputs | Six configurable control outputs. Each is made of a switching relay (NO, NC and COM) in parallel with a 24VDC signal. The 24VDC part of the control output can source max 200mA and has overcurrent protection. |

| 6 | Audio Input | Microphone and line-in audio inputs for microphones or external audio sources |

| 7 | Audio Output | One configurable audio output which can be used for analog integration |

| 8 | Optional Audio I/O | Audio inputs/outputs available in the system if the optional AGA board is inserted in the ESC1 |

| 9 | Ground Connection | Ground connection for grounding of the unit. This is connected in parallel with the ground connection in the AC power inlet |

| 10 | DC Power Inlet | DC power inlet for 24 to 48 VDC |

| 11 | AC Power Switch | Power switch for AC power. This switch will not turn off the system controller if DC backup is connected |

| 12 | AC Power Inlet | AC power inlet for 110 to 230 VAC. The power inlet has a V-Lock mechanism for a secure connection |

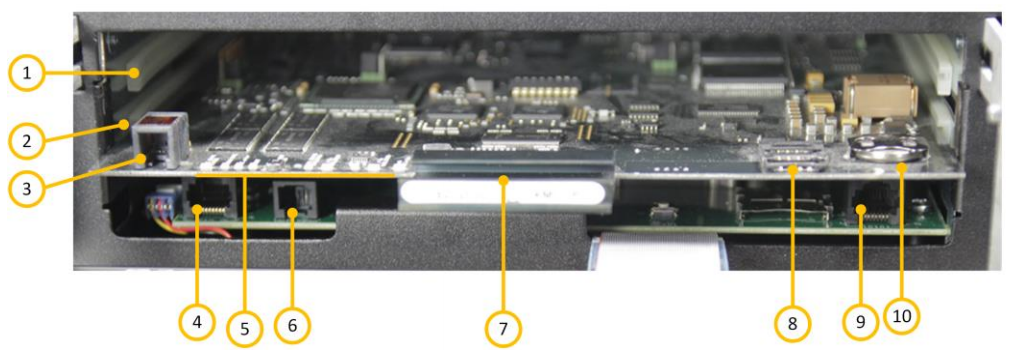

Overview - Internal

| 1 | Feature board slot | Slot for an optional feature board like the AGA board for 12 additional audio inputs/outputs |

| 2 | PSC slot | Slot for the primary system controller board |

| 3 | PSC Hotswap | |

| 4 | PSC Eth0 | |

| 5 | Status indicators | Local status indicators for the primary system controller board |

| 6 | Hotswap | |

| 7 | Primary System Controller | Primary System Controller board for the ESC1 |

| 8 | SIM card | SIM card containing the ESC1’s MAC address and basic settings |

| 9 | SSC Serial Connector | |

| 10 | Battery | Battery for the time clock |

Placement

The ESC1 can be l ocated anywhere in the equipment rack. It is however advisable to install it at eye-level as this will make it easier to operate the user interface on the display.

Mounting

The ESC1’s mechanical construction is rigid enough to be mounted using only the four holes in the mounting flange to secure it to the rack. It is however considered good practice to mount support rails if the system is installed in a moving environment.

Power Supply

The ESC1 shall be connected to the equipment rack’s primary and secondary (emergency) source of power.

The requirements for the power rails are listed in Table 3. The cables used for power shall be dimensioned accordingly to the voltage and current consumption of the ESC1.

Only one power source may be connected if the power source itself is redundant (e.g. UPS) or if the class/installation permits a single source of power.

Both power inputs are equipped with a lock, preventing the plug from falling out. Make sure that the plug is properly inserted, and that the lock is engaged.

Grounding

It is always good practice to ground the cabinet of equipment installed in racks. This ensures safety and good EMC. If the unit is powered entirely through the DC power inlet, the ground connection is the only way to connect the ESC1 to ground. The grounding connection of the ESC1 should be connected to the equipment rack’s ground strip using a ground wire of at least 0.75 mm² (AWG 19).

Installing Primary System Controller Board

The primary system controller (PSC) or AMC-IP board must be inserted into the system controller. Before inserting the PSC board into the system controller, the SIM card containing the MAC address and basic settings must be inserted into the board. The SIM card shall be mounted in the socket located in the lower corner of the board (See Figure 10) by sliding the metal retention clip back and flipping the lid open (the lid itself comprises the socket). The SIM card itself shall then be inserted into the socket before closing it and the retention clip fastened.

To install the PSC board, the front cover must be opened by unscrewing the two front cover retention screws. Open the front cover by pulling it out (using the two loosened screws as handles) and flipping it down. The PSC board shall be inserted in the lowest position.

Disconnect all power from the ESC1 before installing or removing the PSC board

Configuration data for all units in the system is stored in nonvolatile memory on the PSC board

Ethernet Connections

The ESC1 shall be connected to the network using one or two Ethernet cables, depending on the system interconnection scheme.

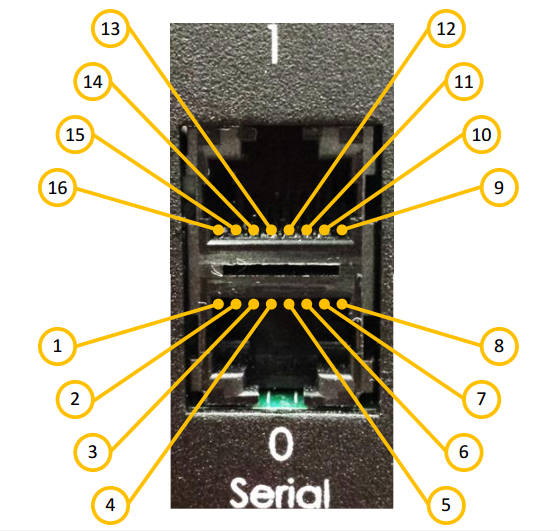

Serial Port Connections to PSC

The ESC1 is equipped with two serial ports on the PSC board, which can be used for external equipment integration. Serial port 0 offers RS232 only and is most commonly used for console access. Serial port 1 can be configured as either RS232 or RS422. The baud rate for both ports is configurable through software.

| 1 | Pin 1 - Not used | 9 | Pin 1 - RS422 Tx+ | |

| 2 | Pin 2 - Not used | 10 | Pin 2 - RS422 Tx- | |

| 3 | Pin 3 - RS232 Tx | 11 | Pin 3 - RS232 Tx | |

| 4 | Pin 4 - GND | 12 | Pin 4 - GND | |

| 5 | Pin 5 - GND | 13 | Pin 5 - GND | |

| 6 | Pin 6 - RS232 Rx | 14 | Pin 6 - RS232 Rx | |

| 7 | Pin 7 - Not used | 15 | Pin 7 - RS232 Rx+ | |

| 8 | Pin 8 - Not used | 16 | Pin 8 - RS232 Rx- |