Difference between revisions of "EAPFX-6"

Rlorentzen (talk | contribs) (→Dimensions) |

Rlorentzen (talk | contribs) |

||

| Line 12: | Line 12: | ||

| − | The EAPFX-6 is a rugged call panel, developed for harsh offshore environments and hazardous areas. The antistatic plastic | + | The EAPFX-6 is a rugged call panel, developed for harsh offshore environments and hazardous areas. The antistatic plastic housing withstands corrosion from the most common corrosive gas and compounds found in this type of environment. The access panel features six fully programmable buttons, which can be used to manually initiate fire alarms, gas alarms or any other action in the Exigo system. The access panel is equipped with indicators to show the status of the power supply, call activity and whether a fault is present in the system. The access panel’s buttons features two independent status indicators each, which shows the status of the related button’s function. The access panel is fully digital, and connects to the Exigo system over a single-pair cable. The access panel is fully monitored to ensure detection of any fault which may compromise the system’s functionality. |

| − | housing withstands corrosion from the most common corrosive | ||

| − | The | ||

| − | or any other action in the Exigo system. The access panel is equipped with indicators to show the status of the power | ||

| − | supply, call activity and whether a fault is present in the system. The access panel’s buttons features two independent | ||

| − | status indicators each, which shows the status of the related button’s function. The access panel is fully digital, and | ||

| − | connects to the Exigo system over a single-pair cable. The access panel is fully monitored to ensure detection of any fault | ||

| − | which may compromise the system’s functionality. | ||

== Additional documentation == | == Additional documentation == | ||

| Line 29: | Line 22: | ||

<br style="clear:both;" /> | <br style="clear:both;" /> | ||

| − | == Connections == | + | === Connections === |

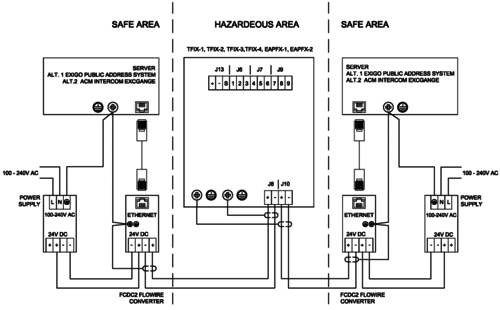

| + | [[File:Turbine EX Connections.PNG]] | ||

| + | |||

| + | === Flowire Connection === | ||

| + | The EAPFX-1 features two Flowire connectors. Power and signal redundancy can be achieved by utilizing both Flowire connectors in an A-B system configuration. | ||

| + | |||

| + | [[File:Note.PNG]] '''Do not connect more than 9 Ex Products to each central Flowire Converter''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''Only use one of the Flowire connectors on each Ex product for each central Flowire Converter''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''Load sharing power supply must be used for redundant cabling solutions.''' | ||

| + | '''Consult with Zenitel before implementing this type of solution.''' | ||

| + | |||

| + | [[File:EX Flowire 1.PNG|thumb|left|500px|The main board receives both power and Ethernet signals through two wires. You can connect either A or B for connection to the rest of the system, or both A and B, each to a separate server, in order to achieve redundancy.]] | ||

| + | <br style="clear:both;" /> | ||

| + | |||

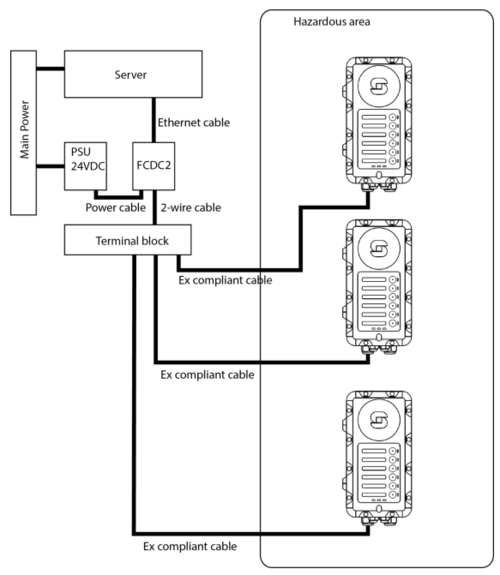

| + | [[File:EX Flowire Single 1.PNG|thumb|left|500px|Connection of Flowire in a single system.]] | ||

| + | <br style="clear:both;" /> | ||

| + | |||

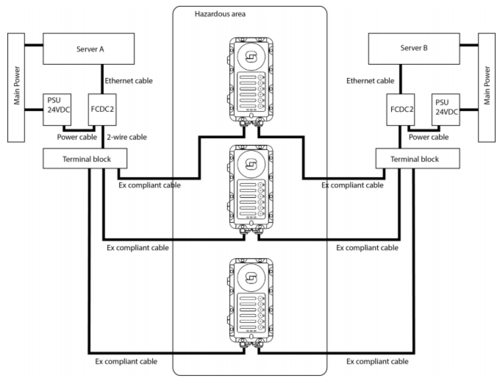

| + | [[File:EX Flowire Redundant 1.PNG|thumb|left|500px|Connection Flowire in a redundant A–B system.]] | ||

| + | <br style="clear:both;" /> | ||

| + | |||

| + | === Central connection === | ||

| + | The central rack must contain | ||

| + | * A server | ||

| + | * A Flowire Converter ([[FCDC-2]]) | ||

| + | * A 24V Power Supply Unit (PSU) | ||

| + | In order to connect several Ex Products to one central FCDC-2, you also need a terminal block. | ||

| + | |||

| + | [[File:EX Flowire Central Server1.PNG|thumb|left|500px|Industrial Ex products connected to a central server.]] | ||

| + | <br style="clear:both;" /> | ||

| + | |||

| + | [[File:EX Flowire Redundant Servers1.PNG|thumb|left|500px|Industrial Ex products connected to two central servers in a redundant A-B system.]] | ||

| + | <br style="clear:both;" /> | ||

| + | |||

| + | [[File:Note.PNG]] '''Only use 24VDC power supplies sold or recommended by Zenitel for Ex products''' | ||

| + | |||

| + | === Grounding === | ||

| + | [[File:Note.PNG]] '''To establish explosion-proof protection, it is vital that''' | ||

| + | '''the grounding of the panel is done according to the following instructions.''' | ||

| + | All ground and shield cables from the central rack must be terminated on the ground sheet inside the main housing. Grounding must be done according to IEC 60079-17. | ||

| + | |||

| + | The apparatus does not withstand the electrical strength test with 2 x Um 250V r.m.s. to earth according to clause 6.3.13 of IEC/EN 60079-11: 2011/2012, because the equipment has a connection to earth. | ||

| + | |||

| + | === Cable insertion === | ||

| + | [[File:Note.PNG]] '''Only cables certified for use in explosive atmospheres shall be used''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''Only Ex certified cable entries made from plastic shall be used.''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''The prescribed cable diameters and other guidelines for cable entries used shall be observed''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''The relevant mounting directives for the cable entries used shall be observed''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''When using cable entries with a degree of protection that differs from the IP protection of the''' | ||

| + | '''Ex Product (see Technical Specifications), the limiting IP protection level shall be adhered to.''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''When using cable entries with an ambient temperature range that differs from the ambient temperature''' | ||

| + | '''range of the panel or intercom (see Technical Specifications), the limiting temperature range shall be adhered to''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''When using cable entries with impact resistance that differs from the impact resistance of the panel | ||

| + | '''or intercom, the limiting impact resistance shall be adhered to''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''Cable entries must have ingress protection IP54 or higher''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''Cable entries must be approved according to IEC 60079-0:2007 or EN 60079-0:2009 or''' | ||

| + | '''later versions of one of these standards''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''In order to ensure the required minimum degree of protection, the cable entries must be tightened down securely.''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] '''Over-tightening can impair the degree of protection and damage the Ex Product''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''When tightening the cap nut of a cable entry, a suitable tool shall be used to prevent the gland from twisting''' | ||

| + | <br> | ||

| + | [[File:Note.PNG]] | ||

| + | '''When using the Hummel M16 cable gland HSK-K-MZ-Ex included in the box, the following limiting factors apply''' | ||

| + | <br> | ||

| + | - Lowest temperature -20°C | ||

| + | - Impact resistance: 4J (low risk of mechanical danger) | ||

== Dimensions == | == Dimensions == | ||

Revision as of 09:33, 3 June 2016

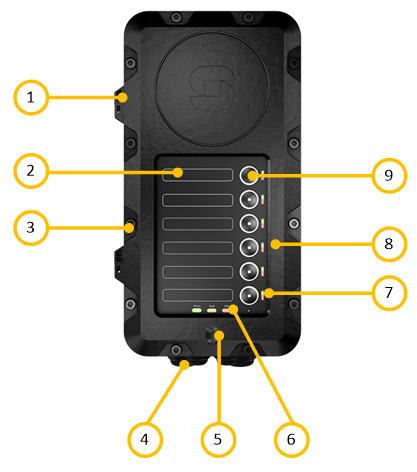

Exigo Industrial Ex Access Panel, 6 Buttons

- Network access panel for explosive atmospheres

- Ex m b ib e IIC T4 Gb

- DSP for acoustic signal processing

- IP networking and power over Flowire technology

- Six programmable buttons with individual labels and status indicators

- Optional button protection covers

- Indicators for power, call and fault

- For single or dual systems (A and B systems)

The EAPFX-6 is a rugged call panel, developed for harsh offshore environments and hazardous areas. The antistatic plastic housing withstands corrosion from the most common corrosive gas and compounds found in this type of environment. The access panel features six fully programmable buttons, which can be used to manually initiate fire alarms, gas alarms or any other action in the Exigo system. The access panel is equipped with indicators to show the status of the power supply, call activity and whether a fault is present in the system. The access panel’s buttons features two independent status indicators each, which shows the status of the related button’s function. The access panel is fully digital, and connects to the Exigo system over a single-pair cable. The access panel is fully monitored to ensure detection of any fault which may compromise the system’s functionality.

Contents

Additional documentation

For more documentation, please visit the Zenitel web page: https://www.zenitel.com/product/eapfx-6

Installation

Overview - Front

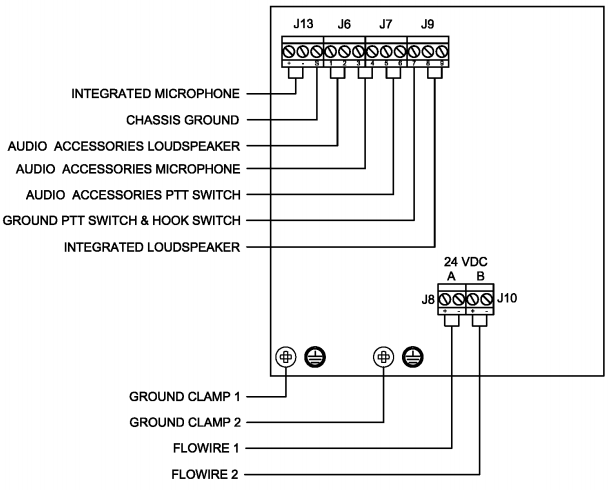

Connections

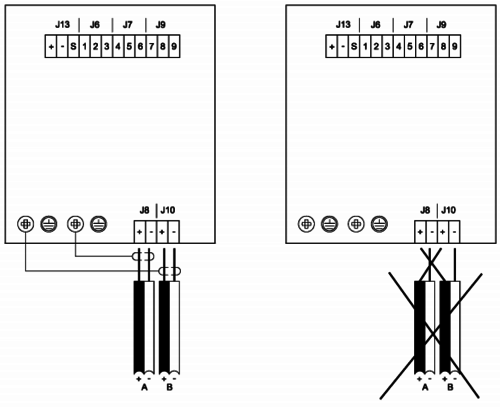

Flowire Connection

The EAPFX-1 features two Flowire connectors. Power and signal redundancy can be achieved by utilizing both Flowire connectors in an A-B system configuration.

Do not connect more than 9 Ex Products to each central Flowire Converter

Only use one of the Flowire connectors on each Ex product for each central Flowire Converter

Load sharing power supply must be used for redundant cabling solutions. Consult with Zenitel before implementing this type of solution.

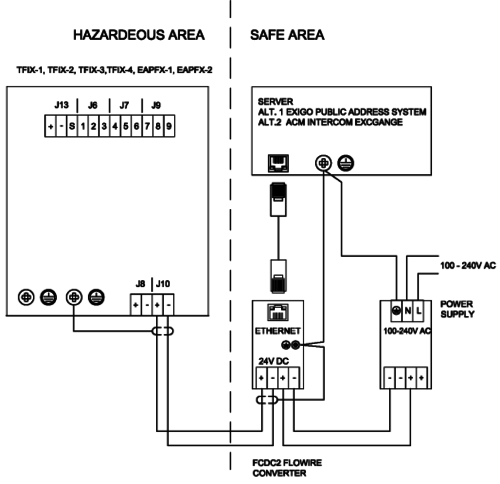

Central connection

The central rack must contain

- A server

- A Flowire Converter (FCDC-2)

- A 24V Power Supply Unit (PSU)

In order to connect several Ex Products to one central FCDC-2, you also need a terminal block.

Only use 24VDC power supplies sold or recommended by Zenitel for Ex products

Grounding

To establish explosion-proof protection, it is vital that the grounding of the panel is done according to the following instructions.

All ground and shield cables from the central rack must be terminated on the ground sheet inside the main housing. Grounding must be done according to IEC 60079-17.

The apparatus does not withstand the electrical strength test with 2 x Um 250V r.m.s. to earth according to clause 6.3.13 of IEC/EN 60079-11: 2011/2012, because the equipment has a connection to earth.

Cable insertion

Only cables certified for use in explosive atmospheres shall be used

Only Ex certified cable entries made from plastic shall be used.

The prescribed cable diameters and other guidelines for cable entries used shall be observed

The relevant mounting directives for the cable entries used shall be observed

When using cable entries with a degree of protection that differs from the IP protection of the Ex Product (see Technical Specifications), the limiting IP protection level shall be adhered to.

When using cable entries with an ambient temperature range that differs from the ambient temperature range of the panel or intercom (see Technical Specifications), the limiting temperature range shall be adhered to

When using cable entries with impact resistance that differs from the impact resistance of the panel or intercom, the limiting impact resistance shall be adhered to

Cable entries must have ingress protection IP54 or higher

Cable entries must be approved according to IEC 60079-0:2007 or EN 60079-0:2009 or later versions of one of these standards

In order to ensure the required minimum degree of protection, the cable entries must be tightened down securely.

Over-tightening can impair the degree of protection and damage the Ex Product

When tightening the cap nut of a cable entry, a suitable tool shall be used to prevent the gland from twisting

When using the Hummel M16 cable gland HSK-K-MZ-Ex included in the box, the following limiting factors apply

- Lowest temperature -20°C

- Impact resistance: 4J (low risk of mechanical danger)